Fuel flexibility without compromising efficiency.

Product Outline

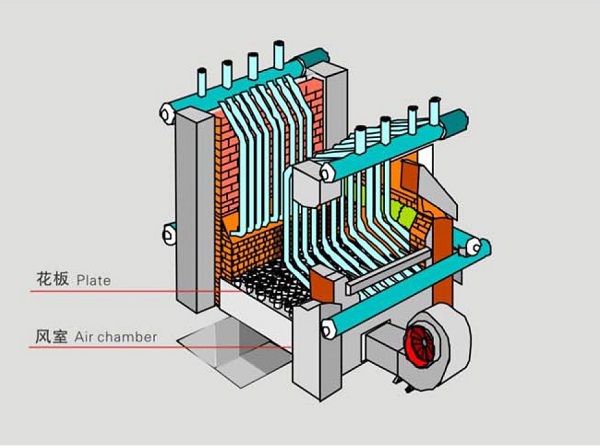

Fortis Nova (Private) Limited offers TUFF Fluidized Bed Combustion (FBC) Boilers, engineered for exceptional fuel adaptability and high combustion performance. These systems are designed to handle a wide range of fuels, making them ideal for industries seeking operational flexibility and cost optimization.

Wide Fuel Adaptability

Wide Fuel Adaptability: TUFF FBC boilers can utilize both coal and biomass, offering reliable combustion of low- to high-calorific-value coal (1,000–7,000 kcal/kg), including challenging fuels such as coal gangue, bone coal, bituminous coal, anthracite, oil shale, and even partially burnt slag from grate-fired boilers. On the biomass side, the system supports diverse agro-waste fuels such as: Rice Husk, Corncobs, Palm Kernel Shells, Wood Chips and similar fuels.

High Combustion Efficiency

With an optimized furnace design and enhanced bed dynamics, TUFF FBC boilers achieve combustion efficiency up to 97%. This is made possible by:

- High bed heat transfer coefficient

- Elevated heat load per unit furnace cross-section

- Complete burnout of fuel, including low-volatile materials

Operational Reliability:

The system features:

- Excellent thermal insulation, minimizing heat loss

- Fast and convenient start-up/shutdown, suitable for fluctuating industrial loads

- Advanced dust collection systems, meeting strict emissions standards

- High fuel flexibility, accommodating variation in fuel supply and formulation

In an era of rising fuel costs and energy uncertainty, TUFF’s FBC technology delivers both economic and environmental value, supporting sustainable industrial operations in Pakistan and beyond.

WE SERVES

We serve a diverse industrial base!

Spanning sectors such as textile, apparel, food processing, edible oil, chemicals, paper and pulp, along with other general industrial users.